Ingevity is the world leader in polycaprolactone technology and innovation, with a 40-year history of helping compounders and converters produce safer, more sustainable and higher performing bioplastics. Our Capa® family of caprolactone-based thermoplastic products are ideally suited for bags and films, rigid packaging, and paper coatings. Ingevity’s Capa team is world-renowned for helping customers improve their existing bioplastics offerings, extending the use of biopolymers, and ultimately creating more competitive products.

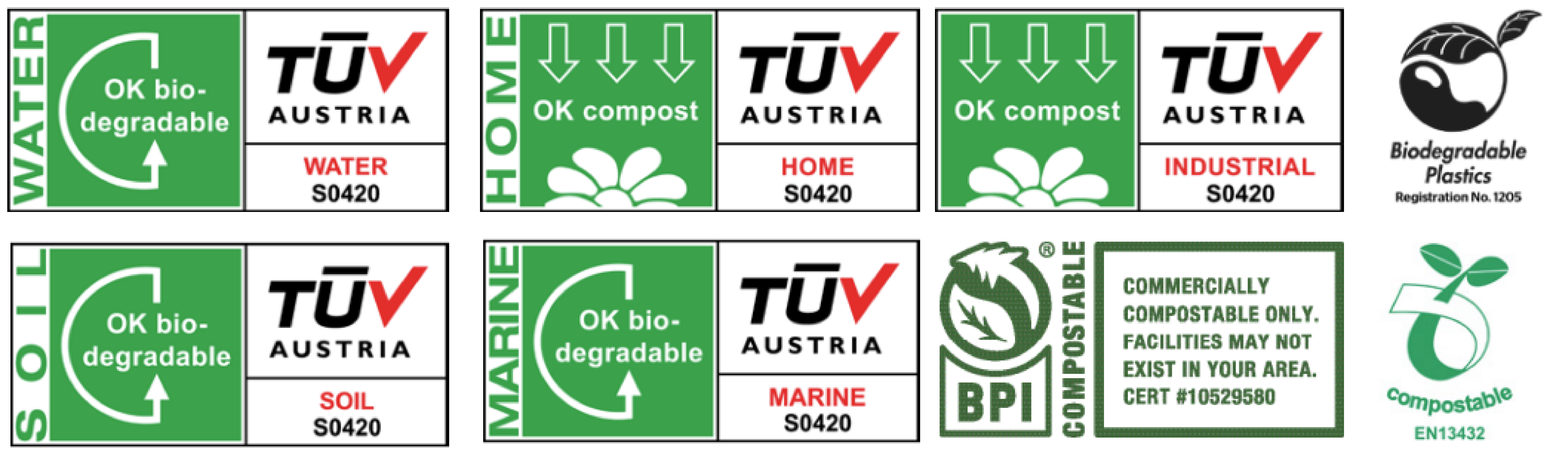

Global certifications

Our certifications from global governing bodies recognize the strong sustainability profile of our Capa portfolio. Ingevity’s certifications include Biodegradable Plastics Institute (BPI), Japanese Bioplastics Association, Seedling and TÜV Austria OK compost HOME, OK compost INDUSTRIAL, OK biodegradable SOIL, OK biodegradable MARINE and OK biodegradable WATER.

Ingevity’s certified biodegradable plastics address the global demand for sustainable products and are becoming a material of choice for a growing number of brands and customers around the world.

Marine and water biodegradability certifications

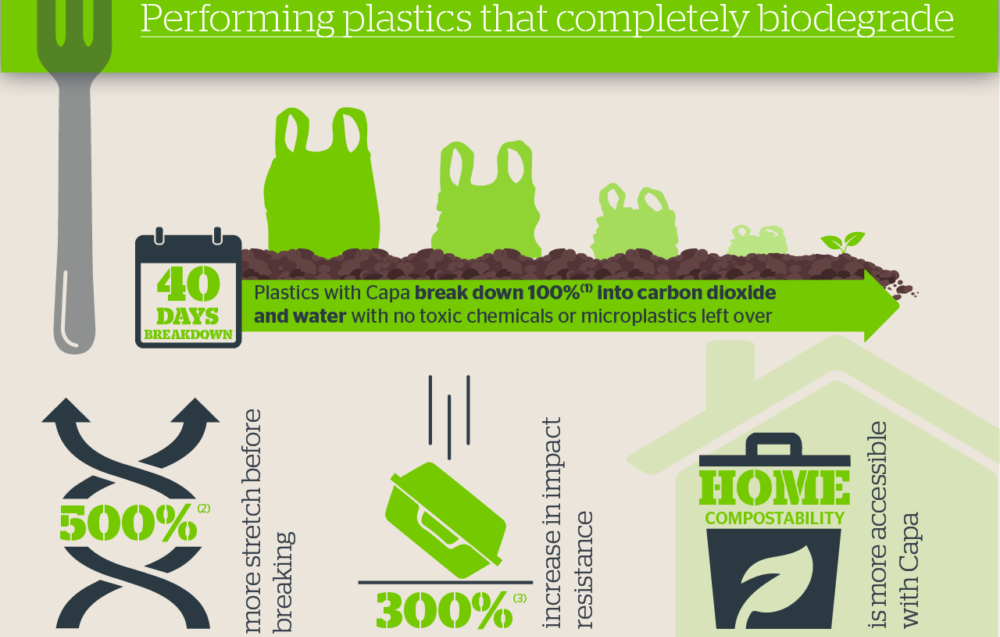

- Ingevity’s portfolio of Capa thermoplastics is one of few bioplastics certified as OK biodegradable MARINE and WATER by TÜV Austria, a distinction requiring materials to achieve complete biodegradation in water environments where much lower temperatures make biodegradability more challenging than land composting conditions.

- By fully biodegrading and avoiding formation of persistent microplastics, Capa’s certified products help customers address water biodegradability requirements of end consumers with ever increasing concerns about environmental pollution in marine and fresh water environments.

Home and industrial compost certifications

- TÜV Austria compost certifications guarantee our engineered polymers meet standards to fully biodegrade in an industrial composting plant and in a home compost heap.

- BPI certified compostable certification confirms Capa thermoplastics can be aerobically composted in industrial facilities and the compost can be cycled back into the soil, leaving behind no toxic residue or microplastics.

Processing advantages

- Easy to process

- Thermally stable

- Broad processing window

Performance advantages

- No packaging degradation with use

- Remains flexible in cold environments

- Fast biodegradability

- Certified compostability

Business advantages

- Higher quality of final bioplastic material means better brand recognition for your final product

- Better processing and stability mean reduced waste

- Home compostability opens new business opportunities